About Us

We Employ the Latest Research Technology

We at GEN Engineering are a single source supplier for Pattern making, machining and casting of aluminium. We do patterns out of wood, aluminium, Cast Iron, Gun- Metal according to the projects’ and customers’ needs. Our complete in-house state of the art capabilities provide the expert facilities to produce castings, machined castings, repair parts with a team of experienced workmen.

We combine our tool making skills with latest designing software technology that meets to every needs of the customer. Our primary focus is quality and customers, GEN Engineering consists a team of expertise, with a field experience over 30 years and we try to meet the highest quality standards possible.

Complete Projects

Experience Staff's

Why Choose Us

We as an organization take maximum efforts towards implementation of proper technology to reduce cost, time of Production, Inspection, Inventory, Rejection & Delays.

High Quality Product

Gem Engineering delivery Perfect High quality product with 100% customer satisfaction.

Qualified Staff

The Development team consisting of qualified and experienced engineers.

Unmatched Expertise

Our Design engineers will analyze the project and advise on it's design feasibility.

New Technology

We used latest designing software technology that meets to every needs of the customers.

Pattern Shop

Our team of Master pattern makers build models and patterns from drawings, samples, prototypes or simply from the concepts or ideas discussed with the customer. These models can be relatively inexpensive and can be used to manufacture foundry tooling and prototype development. In addition to model devel opment, pattern shop employees are able to consult with designers, the CAM Department and the customer to develop prototype tooling and production patterns which are the most cost-effective and efficient.

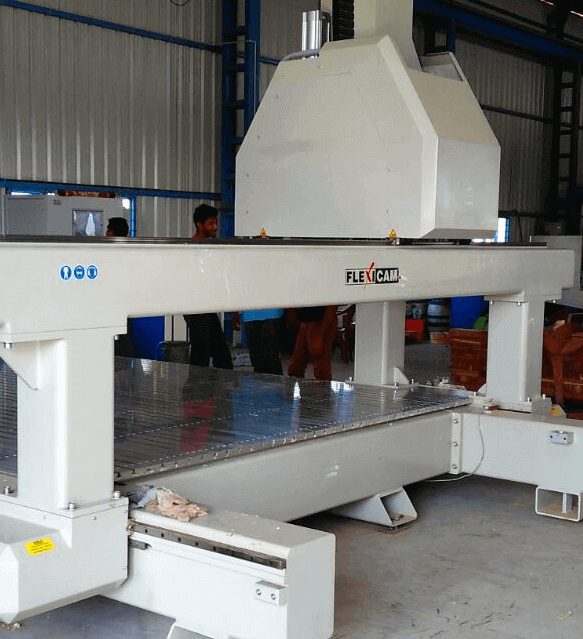

Machining Facility

Our fully equipped Machine shop includes multiple CNC VMC machining centers, which are capable of machining at high speeds, enabling the AWC Company to produce high quality tooling in a reduced timeframe and with a greater lever of accuracy. The Team programming between our CAM department & machine operators along with our advanced software and Capturing Devices allow extremely fast and efficient cutter path generation. Our machining centres allow the company greater flexibility in designing and manufacturing of Patterns and Core Boxes, thus eliminating the need for much more manual additional processes.